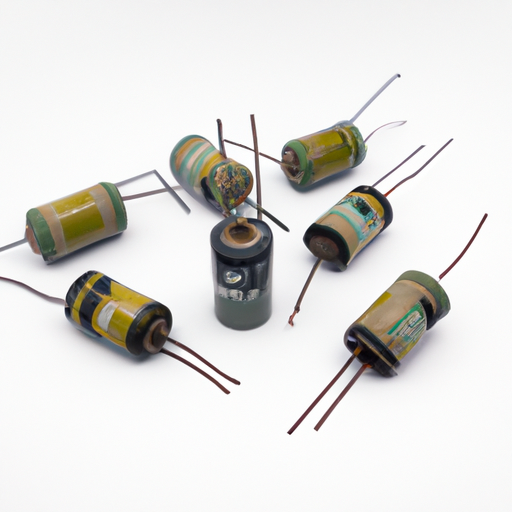

Title: Exploring Purchasing Models for the Latest Film Capacitor Device Components

1. Traditional Distribution Model (200 words) The traditional distribution model involves purchasing film capacitor device components through authorized distributors. These distributors act as intermediaries between manufacturers and end-users, providing a wide range of products from different manufacturers. This model offers several advantages, including a vast product selection, reliable sourcing, and technical support. Additionally, distributors often maintain large inventories, ensuring quick availability of components.

However, the traditional distribution model also has its limitations. The presence of intermediaries can increase the overall cost of components, as distributors add their markups. Moreover, the reliance on distributors for sourcing may lead to longer lead times, especially for rare or specialized film capacitor components. Despite these drawbacks, the traditional distribution model remains popular due to its convenience and comprehensive product offerings.

2. Direct Manufacturer Purchasing (200 words) Direct purchasing from manufacturers is another purchasing model for film capacitor device components. This model eliminates intermediaries, allowing customers to establish a direct relationship with the manufacturer. By bypassing distributors, customers can potentially reduce costs and negotiate better pricing terms. Additionally, direct purchasing offers the advantage of obtaining components directly from the source, ensuring authenticity and quality.

However, direct purchasing may not be suitable for all customers. Manufacturers often have minimum order quantities (MOQs) that may be too high for small-scale buyers. Furthermore, manufacturers may prioritize larger customers, potentially leading to longer lead times for smaller orders. Despite these limitations, direct purchasing can be an attractive option for customers with significant purchasing power or those seeking a closer relationship with the manufacturer.

3. Online Marketplaces (200 words) The rise of e-commerce has revolutionized the purchasing landscape, and film capacitor device components are no exception. Online marketplaces, such as Alibaba, Digi-Key, and Mouser Electronics, provide a platform for manufacturers, distributors, and customers to connect and transact. These marketplaces offer a vast selection of film capacitor components from various manufacturers, making it easy to compare prices and specifications.

One of the key advantages of online marketplaces is the ability to access a global network of suppliers, expanding the range of available options. Additionally, online marketplaces often provide customer reviews and ratings, enabling buyers to make informed decisions. However, customers should exercise caution when purchasing from online marketplaces, as counterfeit or low-quality components may be present. Verifying the reputation and authenticity of sellers is crucial to ensure the purchase of genuine film capacitor device components.

4. Contract Manufacturing (200 words) Contract manufacturing is a purchasing model that involves outsourcing the production of film capacitor device components to specialized manufacturers. This model is particularly suitable for customers who require customized components or have specific design requirements. Contract manufacturers offer expertise in component design, production, and testing, ensuring high-quality and tailored solutions.

By partnering with contract manufacturers, customers can benefit from cost savings, as these manufacturers often have economies of scale and specialized equipment. Additionally, contract manufacturers can provide valuable technical support throughout the product development process. However, this purchasing model may not be suitable for customers with low-volume requirements or those seeking off-the-shelf components.

Conclusion (100 words) The purchasing models for the latest film capacitor device components offer a range of options to cater to the diverse needs of customers. The traditional distribution model provides convenience and comprehensive product offerings, while direct manufacturer purchasing offers potential cost savings and closer relationships. Online marketplaces provide a global network of suppliers, facilitating easy comparison and access to customer reviews. Contract manufacturing is ideal for customers with specific design requirements. By understanding these purchasing models, customers can make informed decisions and ensure the procurement of high-quality film capacitor device components.

Title: Exploring Purchasing Models for the Latest Film Capacitor Device Components

1. Traditional Distribution Model (200 words) The traditional distribution model involves purchasing film capacitor device components through authorized distributors. These distributors act as intermediaries between manufacturers and end-users, providing a wide range of products from different manufacturers. This model offers several advantages, including a vast product selection, reliable sourcing, and technical support. Additionally, distributors often maintain large inventories, ensuring quick availability of components.

However, the traditional distribution model also has its limitations. The presence of intermediaries can increase the overall cost of components, as distributors add their markups. Moreover, the reliance on distributors for sourcing may lead to longer lead times, especially for rare or specialized film capacitor components. Despite these drawbacks, the traditional distribution model remains popular due to its convenience and comprehensive product offerings.

2. Direct Manufacturer Purchasing (200 words) Direct purchasing from manufacturers is another purchasing model for film capacitor device components. This model eliminates intermediaries, allowing customers to establish a direct relationship with the manufacturer. By bypassing distributors, customers can potentially reduce costs and negotiate better pricing terms. Additionally, direct purchasing offers the advantage of obtaining components directly from the source, ensuring authenticity and quality.

However, direct purchasing may not be suitable for all customers. Manufacturers often have minimum order quantities (MOQs) that may be too high for small-scale buyers. Furthermore, manufacturers may prioritize larger customers, potentially leading to longer lead times for smaller orders. Despite these limitations, direct purchasing can be an attractive option for customers with significant purchasing power or those seeking a closer relationship with the manufacturer.

3. Online Marketplaces (200 words) The rise of e-commerce has revolutionized the purchasing landscape, and film capacitor device components are no exception. Online marketplaces, such as Alibaba, Digi-Key, and Mouser Electronics, provide a platform for manufacturers, distributors, and customers to connect and transact. These marketplaces offer a vast selection of film capacitor components from various manufacturers, making it easy to compare prices and specifications.

One of the key advantages of online marketplaces is the ability to access a global network of suppliers, expanding the range of available options. Additionally, online marketplaces often provide customer reviews and ratings, enabling buyers to make informed decisions. However, customers should exercise caution when purchasing from online marketplaces, as counterfeit or low-quality components may be present. Verifying the reputation and authenticity of sellers is crucial to ensure the purchase of genuine film capacitor device components.

4. Contract Manufacturing (200 words) Contract manufacturing is a purchasing model that involves outsourcing the production of film capacitor device components to specialized manufacturers. This model is particularly suitable for customers who require customized components or have specific design requirements. Contract manufacturers offer expertise in component design, production, and testing, ensuring high-quality and tailored solutions.

By partnering with contract manufacturers, customers can benefit from cost savings, as these manufacturers often have economies of scale and specialized equipment. Additionally, contract manufacturers can provide valuable technical support throughout the product development process. However, this purchasing model may not be suitable for customers with low-volume requirements or those seeking off-the-shelf components.

Conclusion (100 words) The purchasing models for the latest film capacitor device components offer a range of options to cater to the diverse needs of customers. The traditional distribution model provides convenience and comprehensive product offerings, while direct manufacturer purchasing offers potential cost savings and closer relationships. Online marketplaces provide a global network of suppliers, facilitating easy comparison and access to customer reviews. Contract manufacturing is ideal for customers with specific design requirements. By understanding these purchasing models, customers can make informed decisions and ensure the procurement of high-quality film capacitor device components.